Our Capabilities

Larsen & Shaw Capabilities

We manufacture a wide variety of custom continuous hinges, architectural products and metal stampings. Our high-speed progressive die presses and brake presses, combined with laser cutting, robotic welding ensure the highest quality standards in minimal time. Our in-house electroplating and electropolishing allow us flexibility and full control over the entire manufacturing process. Coupled with our in-house engineering team, and we are your only choice for all your hinge, laser cut and stamped metal product needs.

Continuous Pin & Barrel Hinges Capabilities

Larsen & Shaw is your one stop shop for all of your precision manufactured hinges, as well as brackets, braces and supports. Our capabilities and quality reputation make us one of the top manufacturers of precision hinges and custom hinges globally. As a custom manufacturer of hinge for over 100 years with plants in both Canada and the United States, we are well positioned to fulfill your needs quickly, and at minimal cost.

As a manufacturer of continuous pin & barrel hinges, Larsen and Shaw has the capability to meet all your hinge needs. Our hinge manufacturing capability includes using a wide range of material gauges, with various pin size knuckle combinations. By now you can likely see why our customers refer to us as the Hinge People® .

An example of some of the continuous pin and barrel hinge combinations can be found in the chart below. Contact us today to discuss your hinge needs.

| Material/Pin (inches) | Open Widths Available | Knuckle | Notes |

|---|---|---|---|

| 024/060 | |||

| 030/080 | |||

| 030/090 | 3/4 to 4 | 0.25 | Quik-A-Line or Stop Feature |

| 040/090 | 7/8 to 4 | 0.25 | Inside stop hinge (~100°) |

| 040/090 | 7/8 to 4 | 0.50 | |

| 040/100 | 3/4 to 6 | 0.50 | |

| 050/125 | 1 to 5-1/2 | 0.50 | |

| 060/125 | 1 to 8 | 0.50 | |

| 060/125 | 3/4 to 3 | 1.00 | Quik-A-Line Feature Available |

| 060/187 | 1-1/4 to 5-3/8 | 1.00 | |

| 060/187 | 1-1/4 to 8 | 2.00 | |

| 060/250 | 1-1/2 to 8 | 2.00 | |

| 075/187 | 3/4 to 3 | 1.00 | |

| 075/187 | 1-1/4 to 8 | 2.00 | |

| 075/250 | 1-1/2 to 5-3/8 | 1.00 | |

| 075/250 | 1-1/2 to 8 | 2.00 | |

| 090/250 | 1-1/2 to 5-3/8 | 1.00 | |

| 090/250 | 1-1/2 to 8 | 2.00 | |

| 120/250 | 2 to 11 | 2.00 | |

| 120/375 | 2 to 11 | 2.00 | |

| 180/500 | 3 to 14 | 2.00 | |

***Capability applies to all metals

Why Use a Continuous Hinge?

There are numerous benefits to using a continuous hinge, some of which include:

- Easier to align and mount during installation.

- Strength (stronger than butt hinges).

- More economical to manufacture.

- Reduces the quantity of hardware inventory that’s required.

- Ease of design for customization in individual applications.

- Lighter gauge of material can be used.

- Better aesthetic appearance.

- Supports the full length of door improving functionality and safety.

In-House Plating and Finishing Options

Our in-house capabilities and breadth of experience allows us to offer numerous finishes at highly competitive prices. We can do so while still retaining our strict process and quality controls to ensure you get the right hinge, every time.

Some examples of our in-house finish options include:

- Electropolish

- Zinc Plated

- Nickel Plated

- Flash Brass (Bright Brass) Plated

- Statuary (Oil-Rubbed) Bronze Plated

- Antique Brass Plated

- Electro-black Plated & Lacquered

We offer a variety of other custom hinge finish options, so please contact us to discuss your needs.

There are numerous benefits to working with Larsen and Shaw to supply all of your continuous hinge, for example:

- We have an ability to custom design to meet your exact hinge specifications.

- We have a large selection of stock items ready to ship at your request.

- We provide high quality post plated finish options that are applied in-house and under strict quality controls

We also have the capability to manufacturer your continuous hinges using any of the following materials & finishes:

- Plain Steel

- Post-Plated Steel

- Stainless Steel

- Electropolished Stainless Steel

- Aluminum

- Solid Brass

- Galvanized

- Others Upon Request

Laser Cut Material Capabilities

Our capabilities and quality reputation have led us to becoming one of the top manufacturers of precision hinges and custom hinges globally.

As a custom manufacturer of hinge for over 100 years with plants in both Canada and the United States, we are aptly known by our customers as the Hinge People™.

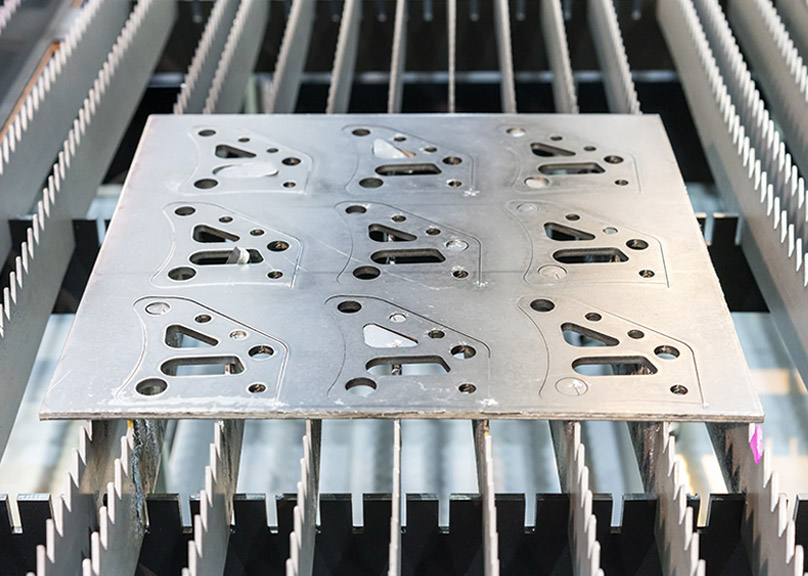

Our manufacturing capabilities include the use of precision lasers, allowing us to make custom hinges, brackets, supports and braces to your exact specifications. In addition to precision, the flexibility of our laser cells also allow us to quickly produce product samples, as well as produce small order volumes.

Materials and Gauges

Our laser cutting capabilities include experience working with all of the metals and material gauges (inches) listed below:

| Material | 24 ga | 22 ga | 20 ga | 18 ga | 16 ga | 14ga | 13 ga | 12 ga | 11ga | 10 ga | 9 ga | 7 ga | 6 ga | 1/4" | 5/16" | 3/8" | 15/32" | 1/2" | Ga. up to |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Carbon Steel | 0.024 | 0.030 | 0.036 | 0.048 | 0.060 | 0.075 | 0.090 | 0.105 | 0.120 | 0.135 | 0.150 | 0.180 | 0.194 | 0.250 | 0.313 | 0.375 | 0.472 | 0.500 | 0.750 |

| Stainless Steel | 0.024 | 0.030 | 0.036 | 0.048 | 0.060 | 0.075 | 0.090 | 0.105 | 0.120 | 0.135 | 0.150 | 0.180 | 0.194 | 0.250 | 0.313 | 0.375 | |||

| Galvanized | 0.028 | 0.034 | 0.040 | 0.052 | 0.064 | 0.079 | 0.093 | 0.108 | 0.123 | 0.138 | 0.153 | 0.144 | 0.162 | 0.250 | |||||

| Copper | 0.020 | 0.025 | 0.032 | 0.040 | 0.050 | 0.064 | 0.080 | 0.093 | 0.125 | 0.156 | 0.187 | ||||||||

| Brass | 0.020 | 0.025 | 0.032 | 0.040 | 0.050 | 0.064 | 0.080 | 0.093 | 0.100 | 0.125 | 0.156 | 0.188 |

Laser Cut Components Capabilities

When it comes to laser cut components, we have vast automated manufacturing capabilities. As an example, we can manufacture laser cut parts and then use metal stamping processing to add forms, hinge knuckles, swages, assembling pins and other shaping. Whatever your custom hinge needs, Larsen & Shaw has the capability to meet them.

Our combined laser cutting and metal stamping capabilities allow us the flexibility of producing products such as:

- Heavy gauge continuous hinges

- Heavy gauge butt hinges

- Specialty hinges in any gauge

- Bracket, braces, supports

Examples of some of these custom heavy gauge continuous hinges, butt hinges and specialty hinges are outlined in the chart below:

Heavy Hinge Pin/Leaf Gauge Combinations

| Leaf Gauge | 0.090" | 0.105" | 0.120" | 0.135" | 0.150" | 0.180" | 0.194" | 0.250" |

|---|---|---|---|---|---|---|---|---|

| 0.188" | X | X | ||||||

| 0.250" | X | X | X | |||||

| 0.312" | X | X | ||||||

| 0.375" | X | X | X | X | X | X | ||

| 0.500" | X | X | ||||||

| 0.625" | X |

Skip to main content

Skip to main content